1. Overview

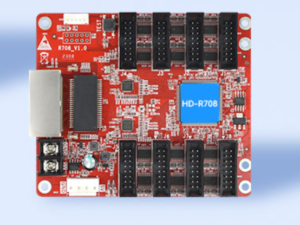

R708 Ton-board 8*HUB75E ports, compatible with R series receiving card, it work with asynchronous sending

card, synchronous sending card and all-in-one LED controller.

2. Interface Description

No. Interface Description

1 Test button Used to test display brightness uniformity and display module flatness.

2 Work indicator

D1 (RUN) flashes to indicate that the control card is running normally. D2

(LAN) flashes quickly to indicate that Gigabit has been recognized and data

is being received.

3 Gigabit Ethernet port Used to connect the sending card or receiving card, the same two network

ports are interchangeable.

4 Power interface Can be accessed with 4.0V ~ 5.5V DC voltage.

5 Power interface Can be accessed with 4.0V ~ 5.5V DC voltage.

6 Flat cable interface 8 HUB75E interface, connect to the LED modules by flat cable.

3. Technical Parameters

Item Parameter value

Rated Voltage (V) DC 4.2V-5.5V

Working Temperature (℃) -40℃~80℃

Working Environment Humidity (%RH) 0~90%RH

Storage Environment Humidity (%RH) -40~90%℃

Net weight (kg) 0.077

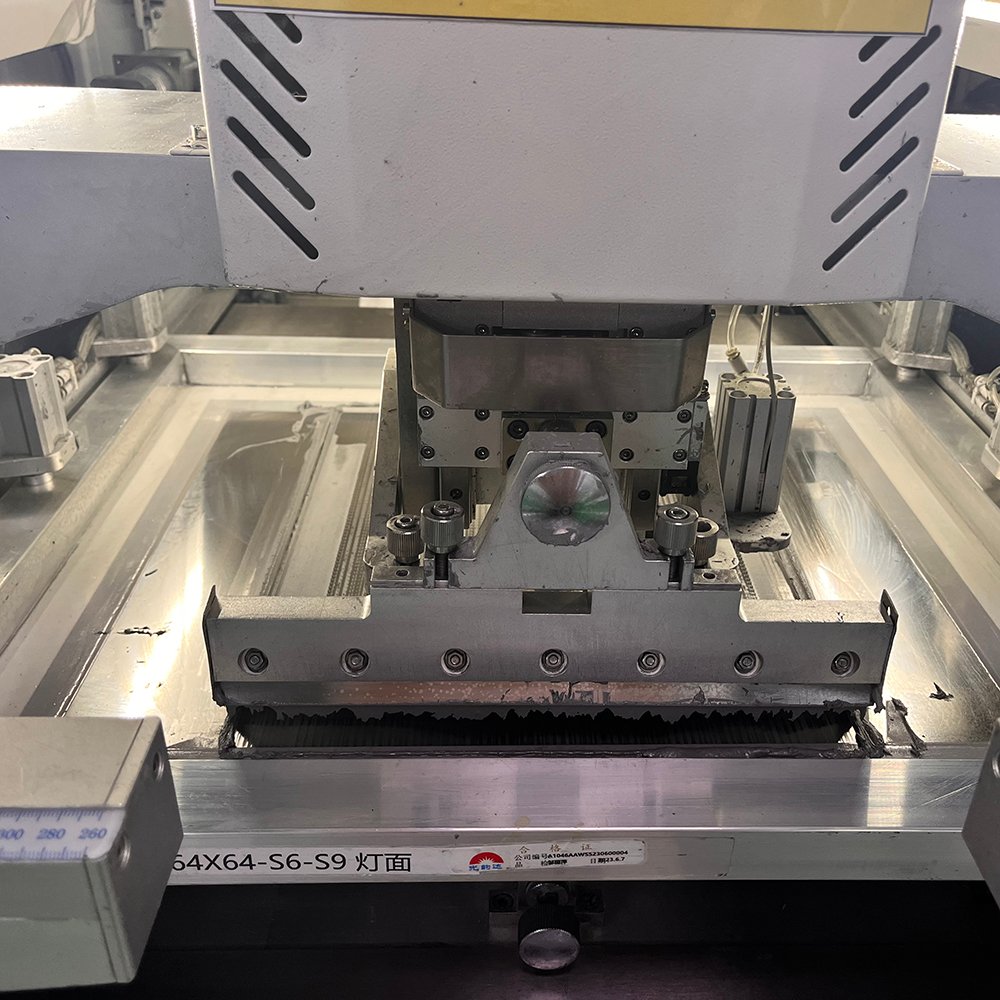

Put the circuit board in the fixture and then place it under a gravity tool to flatten it to the same level.

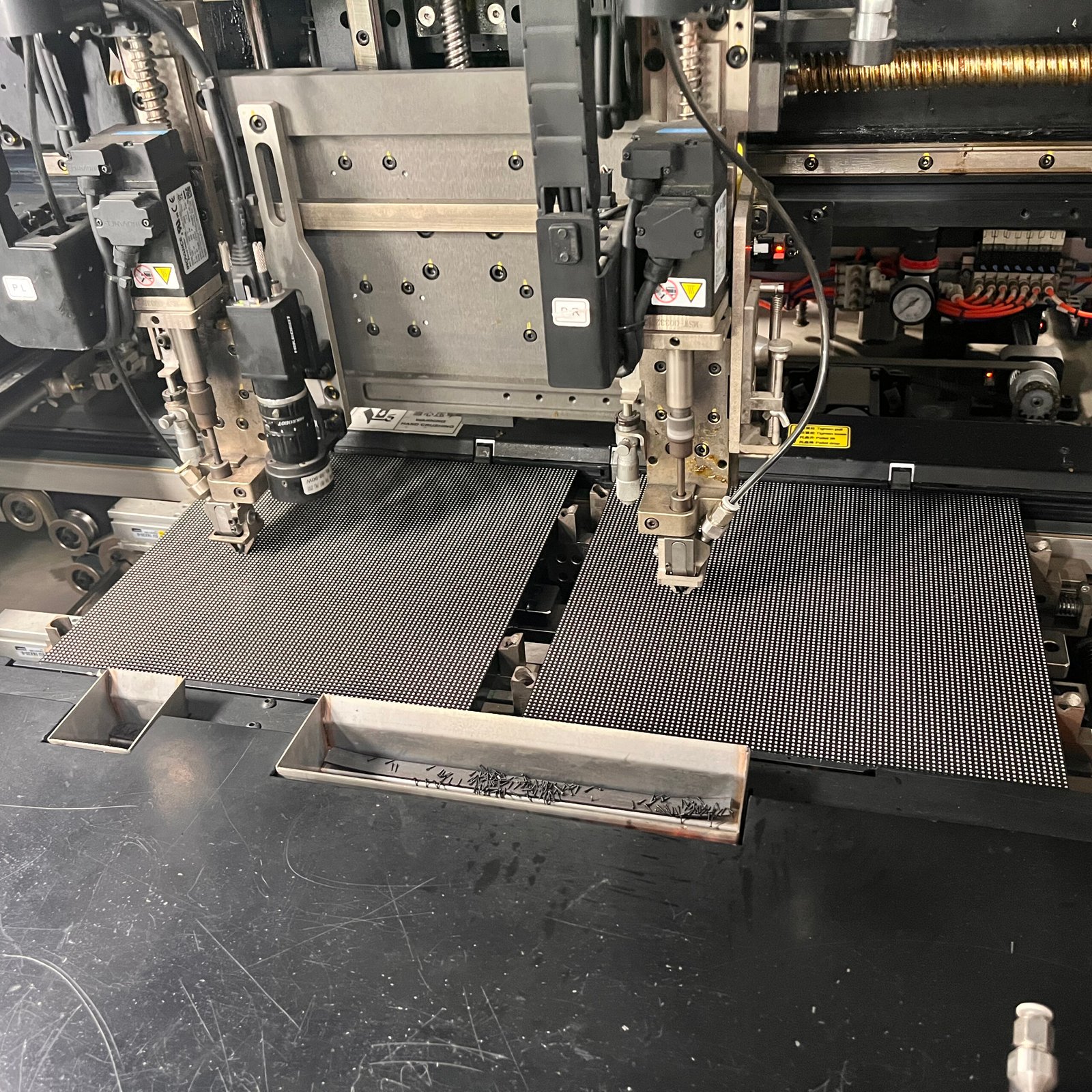

Use a tin brushing machine to evenly brush solder paste on the IC or lamp positions.

.

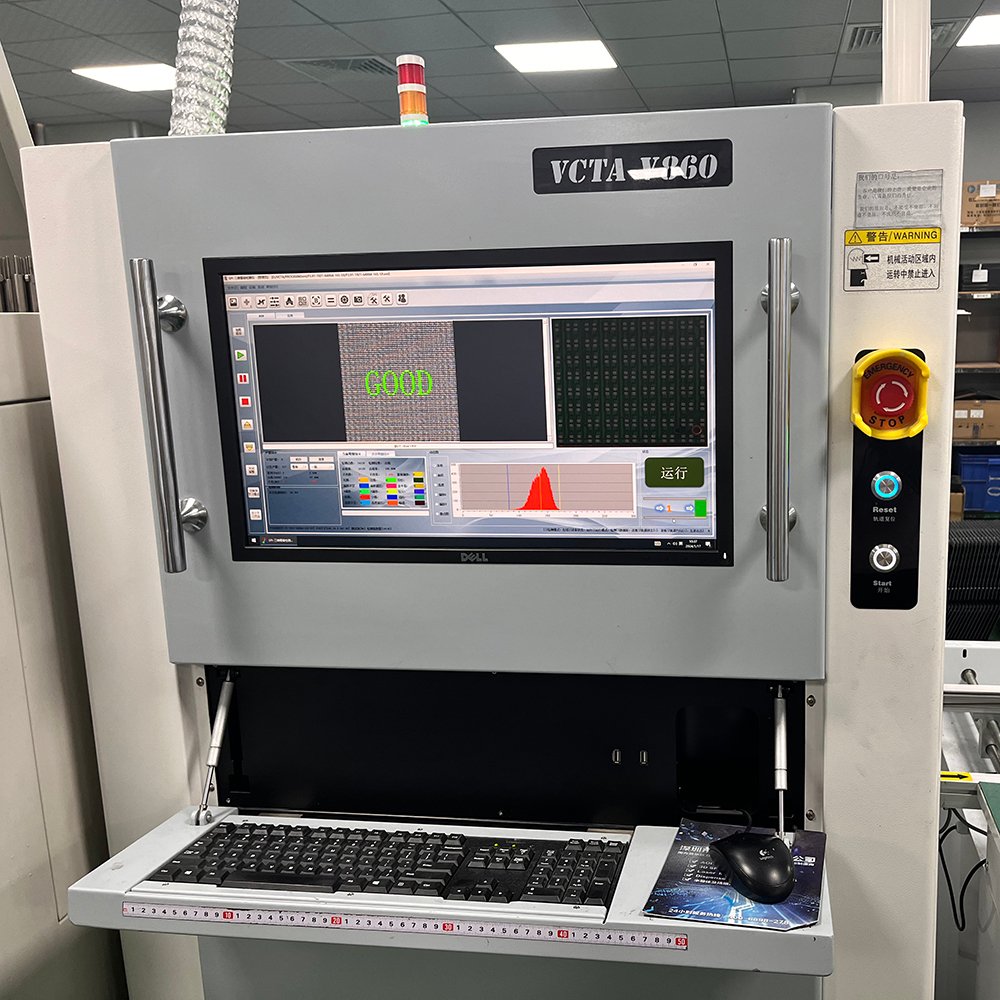

To ensure quality assurance, use testing machines to check if the solder injection points on the circuit board have been coated with solder paste.

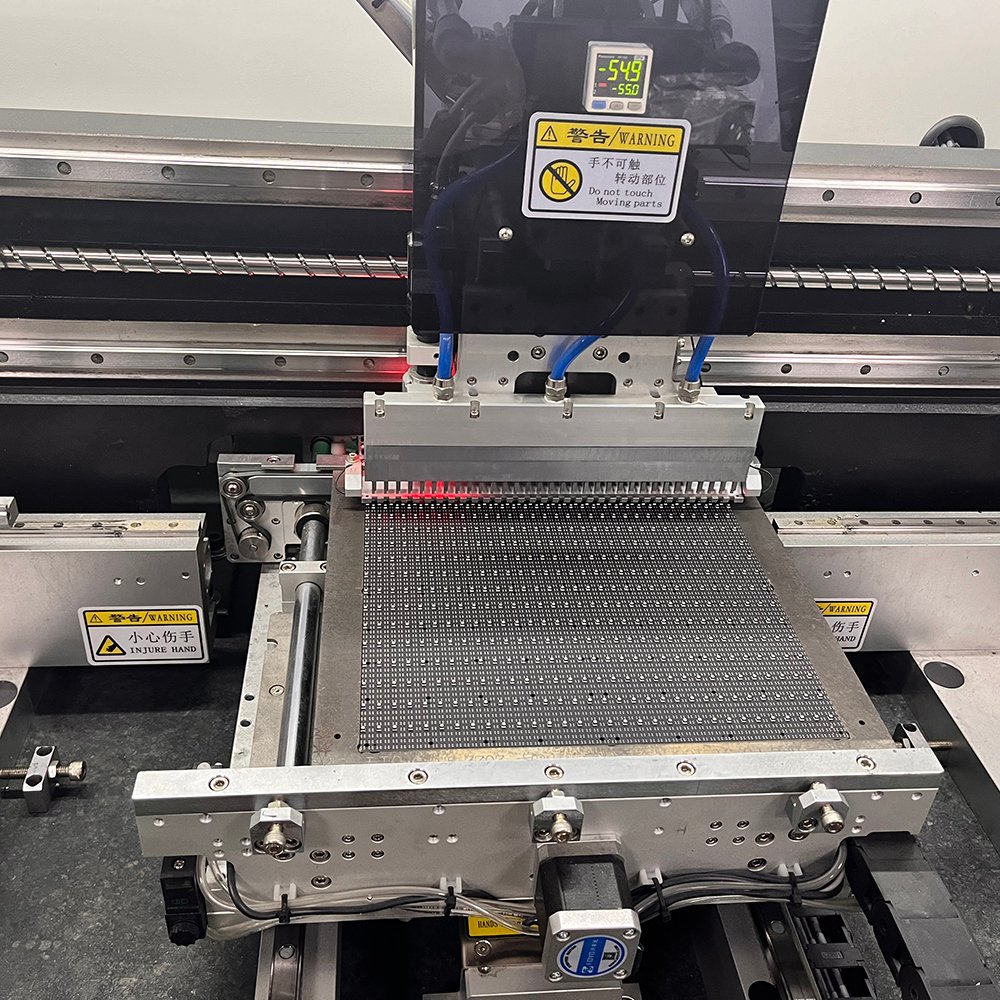

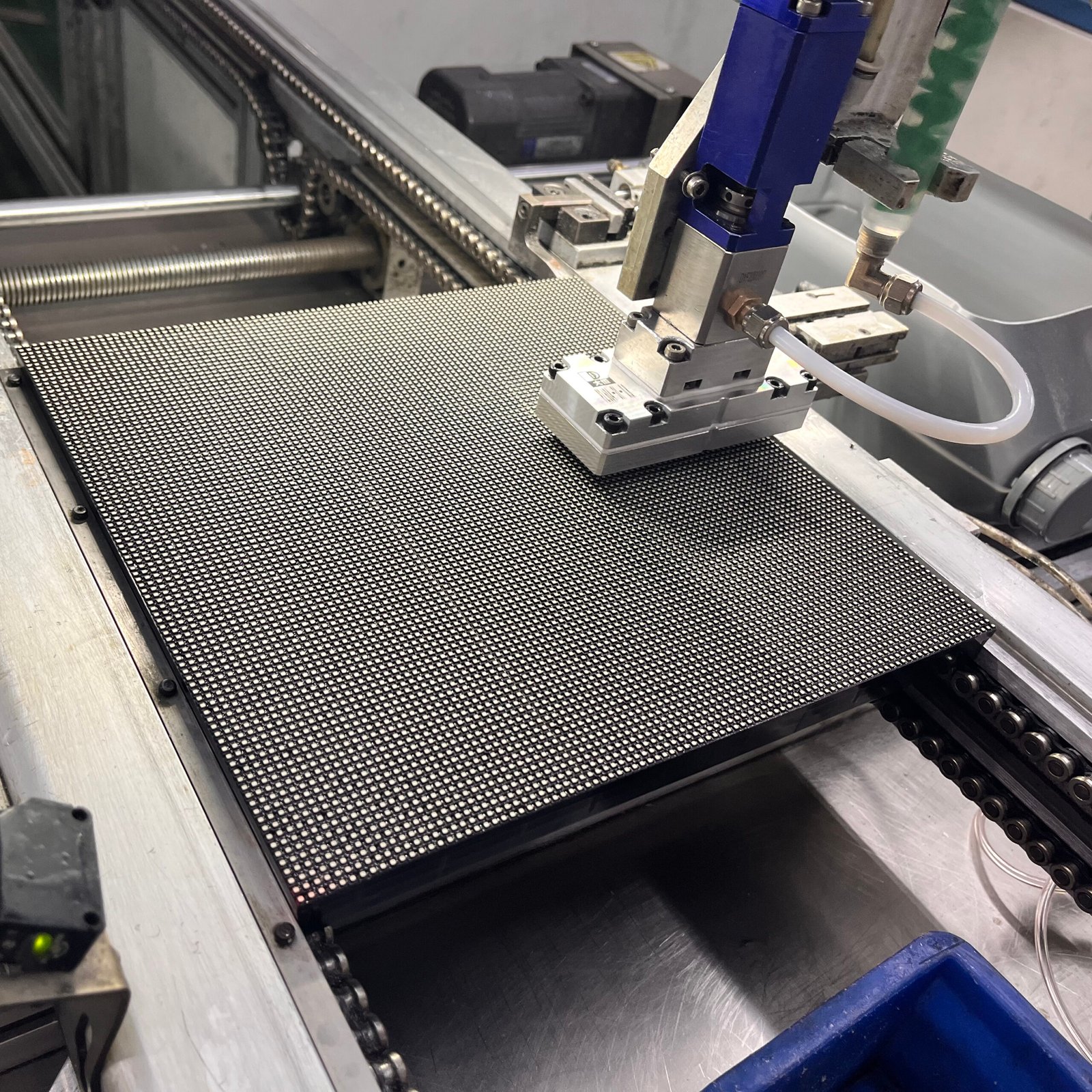

high-speed SMT machine can produce up to 1000 LED modules per day, ensuring timely delivery for our customers.

Use reflow soldering to fix the leds, ICs, capacitors and resistors on the circuit board.

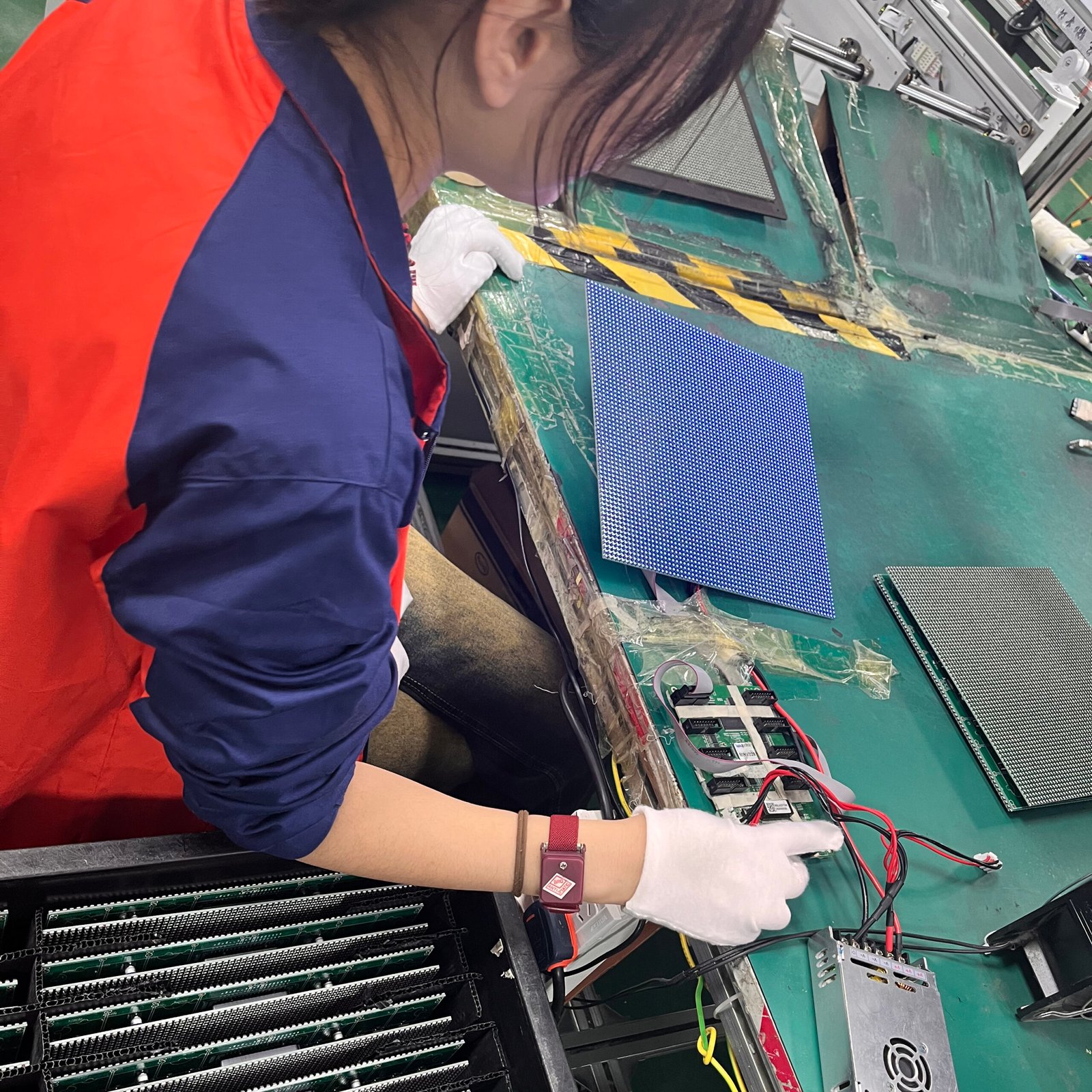

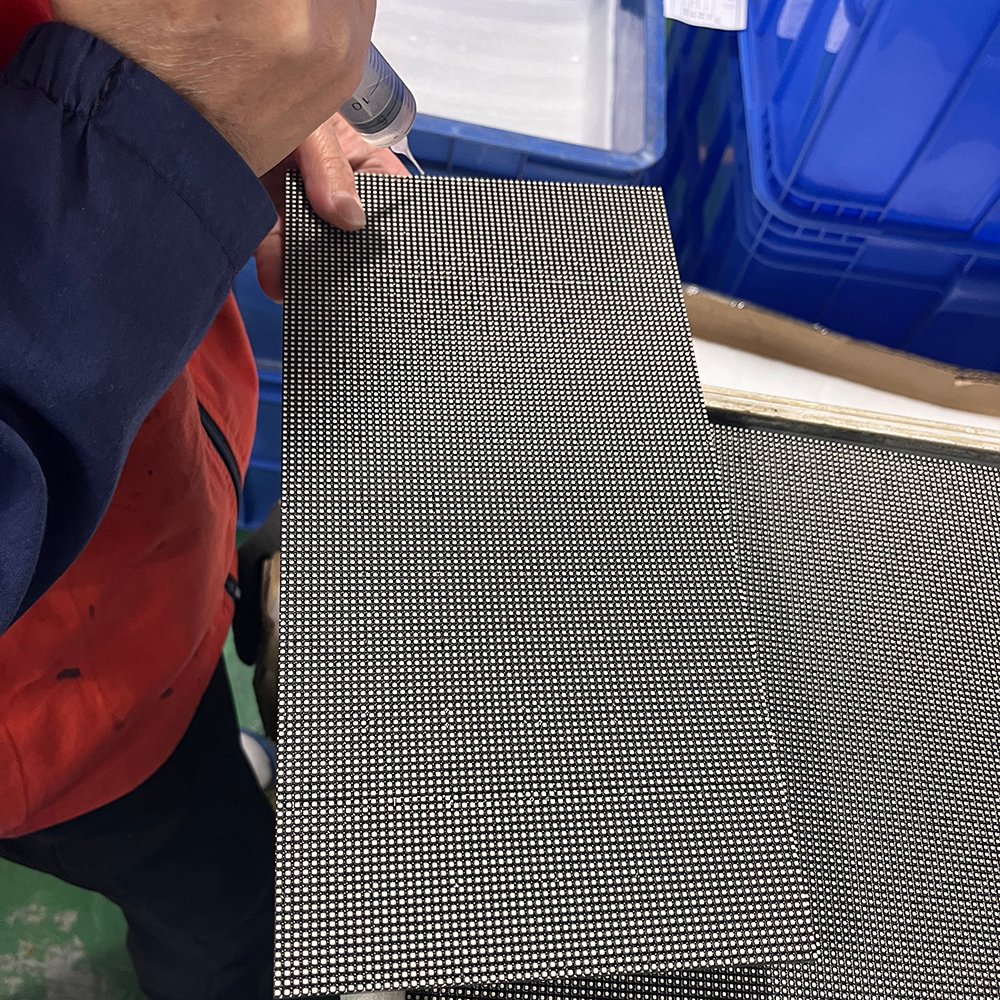

To ensure quality assurance,after fixing all components to circuit board, Will manually test the performance of LED modules.

Automatic Screw Machine: Use the screw machine to fix the circuit board with the bottom shell.

Automatic glue machine: Using an automatic glue machine to glue outdoor LED screen modules to achieve IP65 waterproof level.

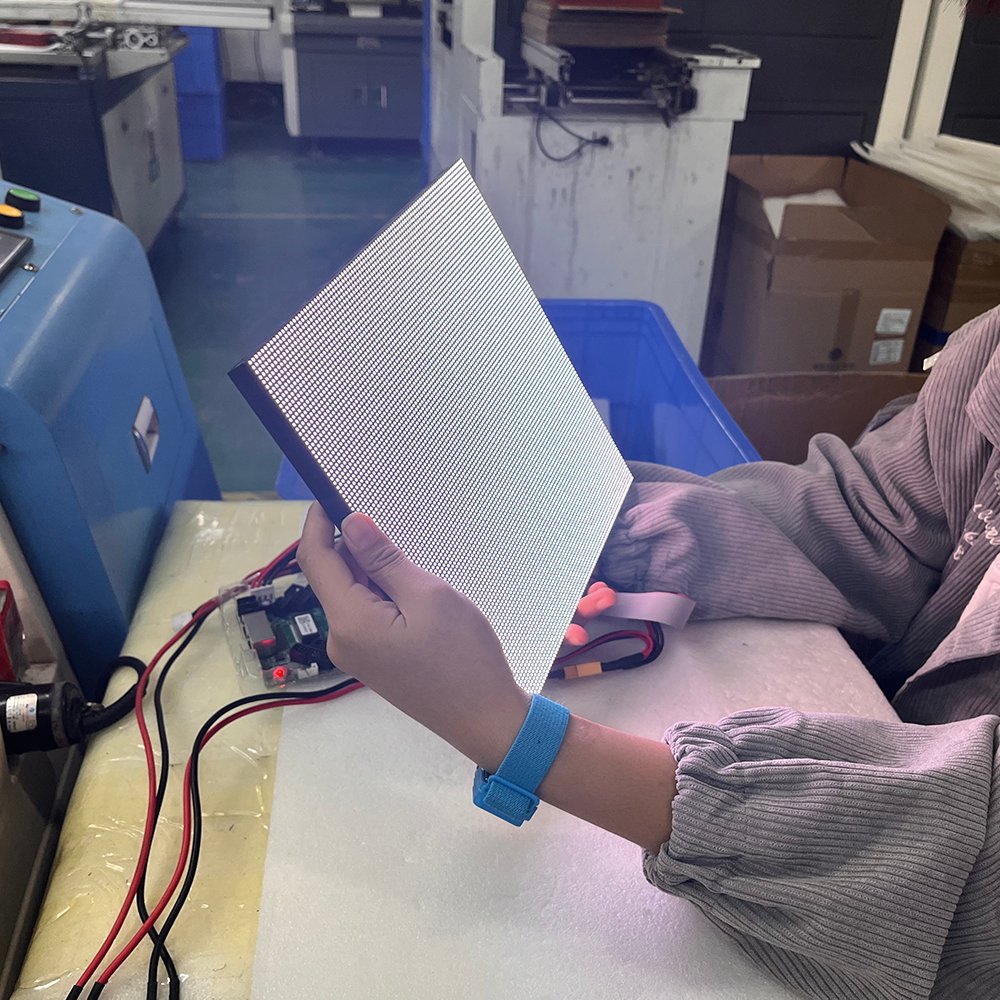

The third door to quality assurance:Check the sealing condition of each module to ensure 100% waterproofing of the product.

The fourth step in quality assurance is to manually test the performance of the finished LED screen module.

Aging test: The finished led screen module undergoes a 48 hours aging test to ensure product quality.

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix”@dhxsigns.com“.

We will contact you within 1 working day, please pay attention to the email with the suffix”@dhxscreen.com“.

Fill out the form below, and we will be in touch shortly.