Thank you for reading this post, don't forget to subscribe!

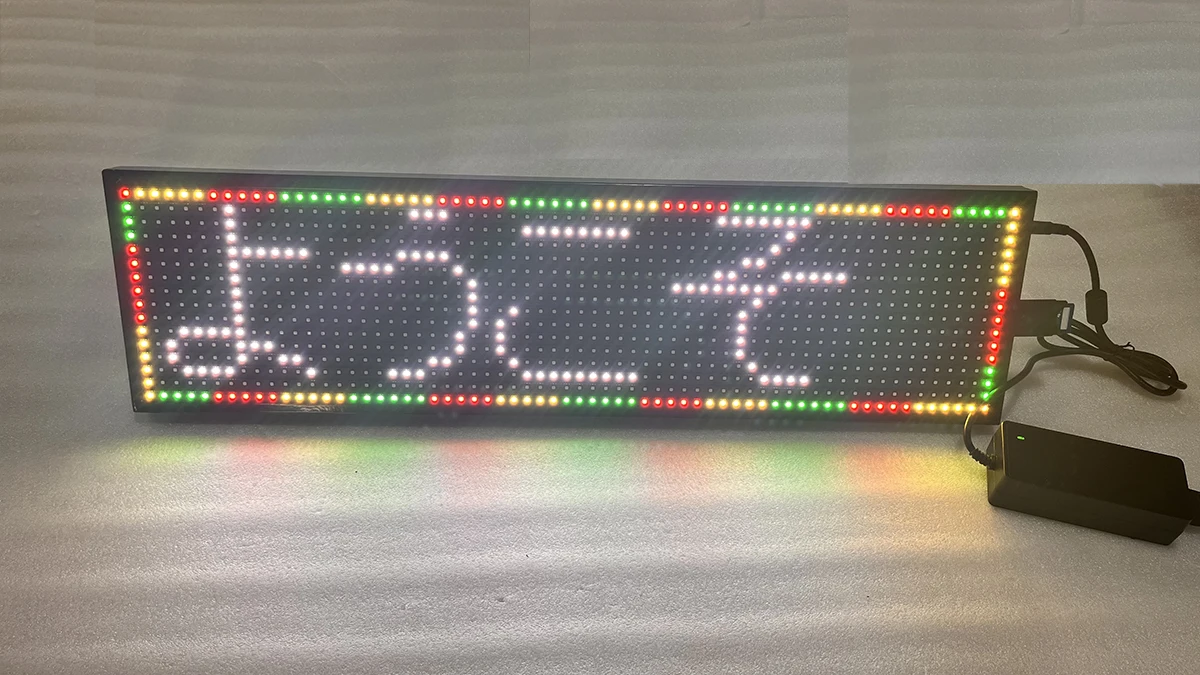

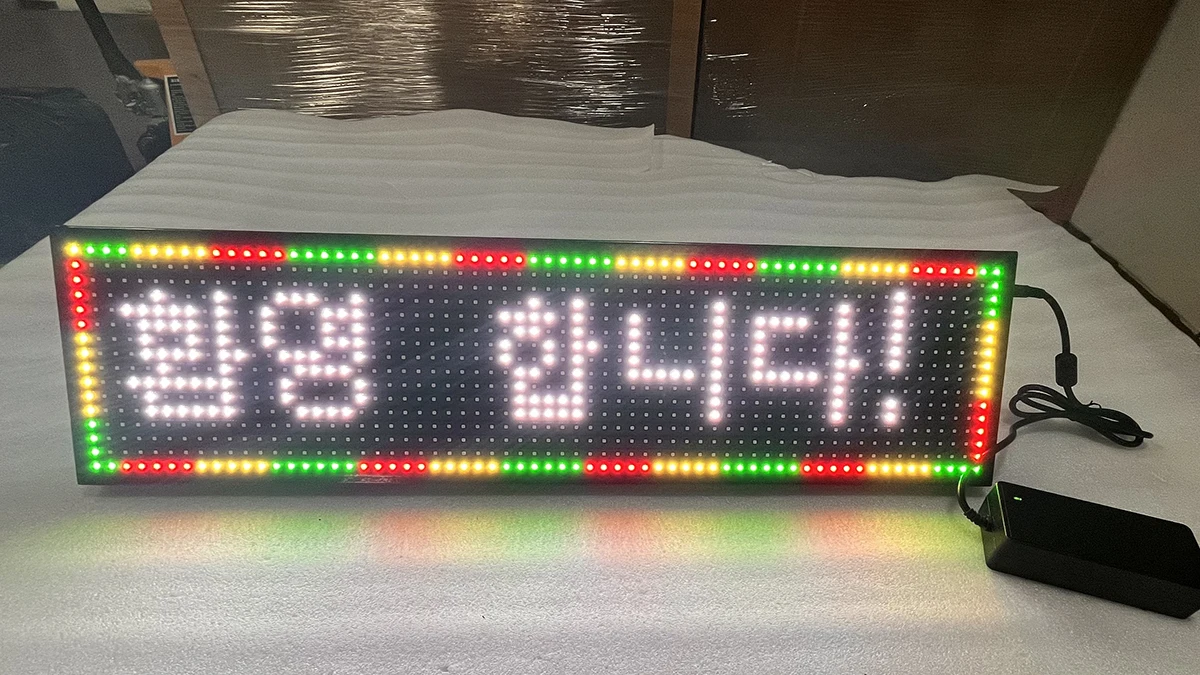

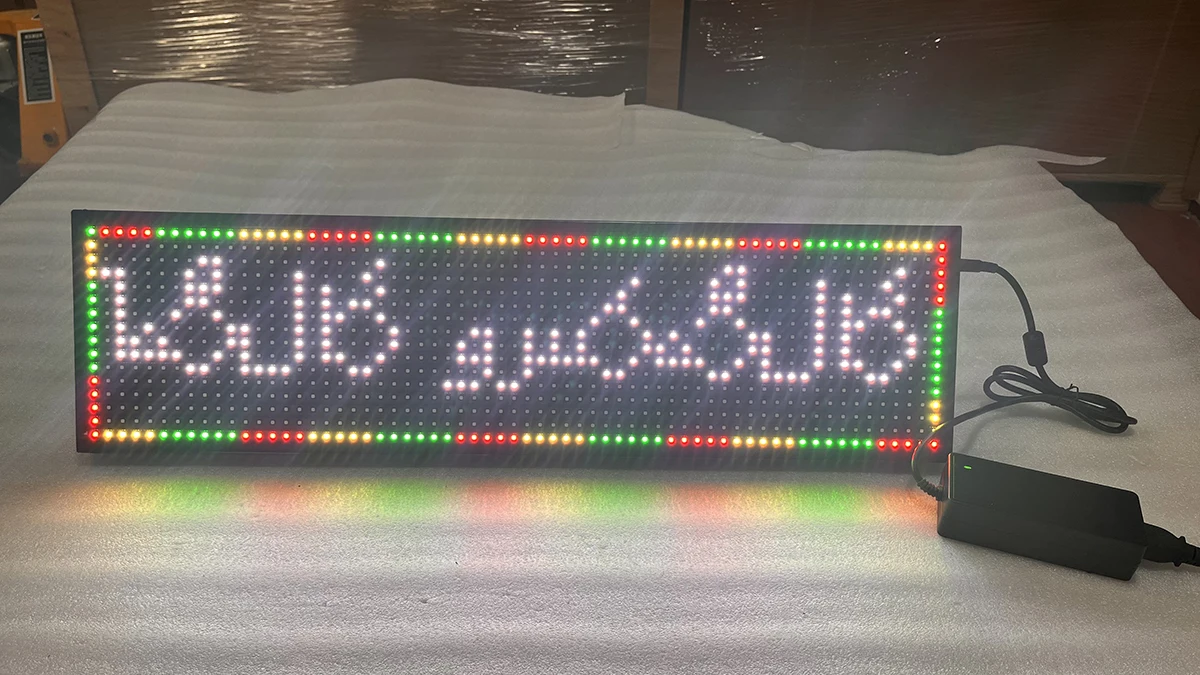

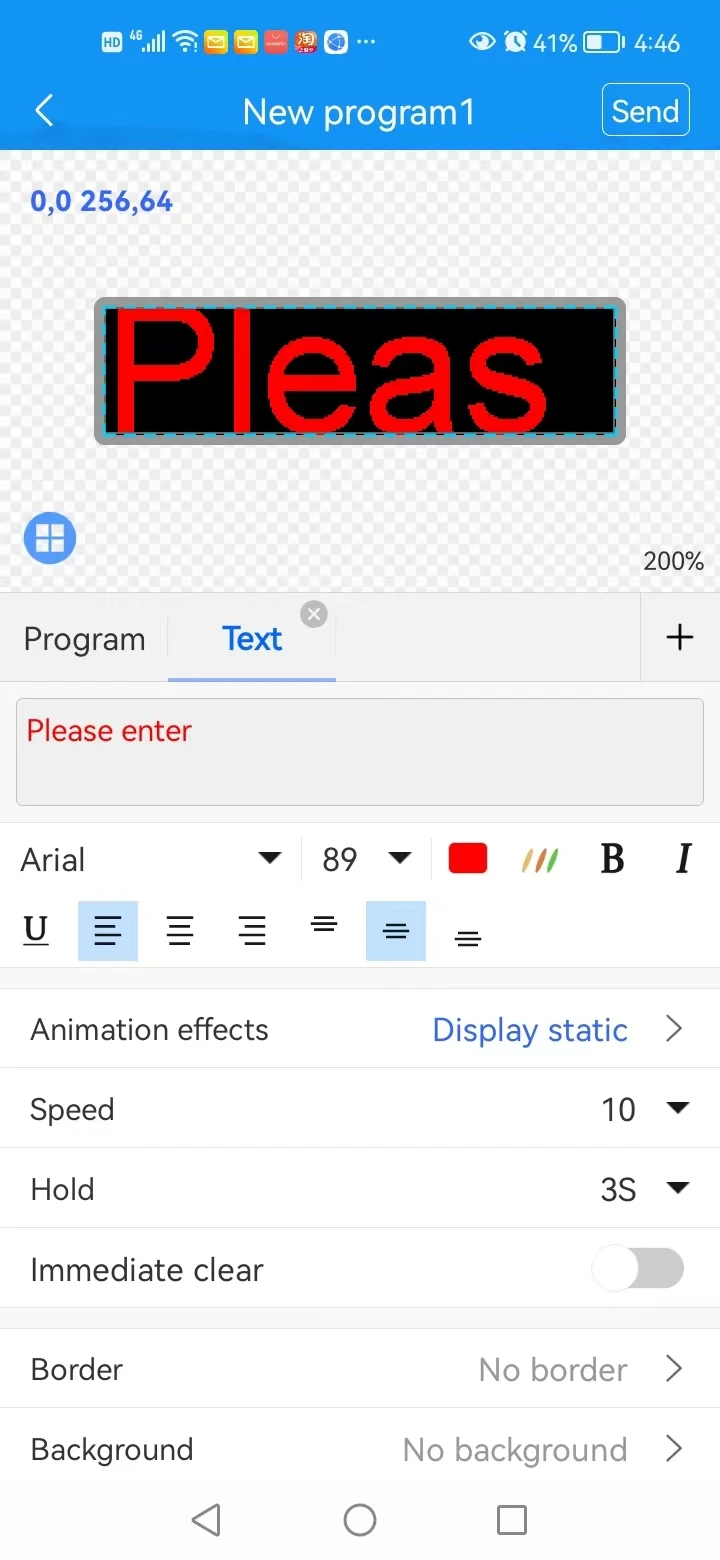

Easy to use, you can edit and send content to the LED screen via mobile phone APP

The second method of control is to edit and send the content to a USB stick on the computer side and then send the content to the led sign via the USB stick port on the screen body.

Specific operating instructions for the two control methods will be packaged with the led sign, or you can contact us to send an electronic file.

FAQ Q1. If you are a factory? A: Yes, we can factory, and focus on led display for 8 years. Q2. Can I have a sample order? A: Yes, we welcome sample order to test and check quality. Mixed samples are acceptable. Q3. What about the lead time? A: Sample needs 5-7 days, mass production time needs 12-25 days. Q4. Do you have any MOQ limit for led screen order? A: Low MOQ, 1pc for sample checking is available Q5. How do you ship the goods and how long does it take to arrive? A: We usually ship by express (DHL, UPS, FedEx ). It usually takes 3-5 days to arrive. Airline and sea shipping also optional. Q6. How to proceed an order for led display? A: Firstly let us know your requirements or application, liking project size, rental or fixed installation. Secondly We quote according to your requirements or our suggestions. Thirdly customer confirms the order and places deposit for formal order. Fourthly We arrange the finished display cabinet. Q7: Do you offer guarantee for the products? A: Yes, we offer 2 years warranty to our products. Keyword:P10 led sign,LED message sign,led scrolling sign

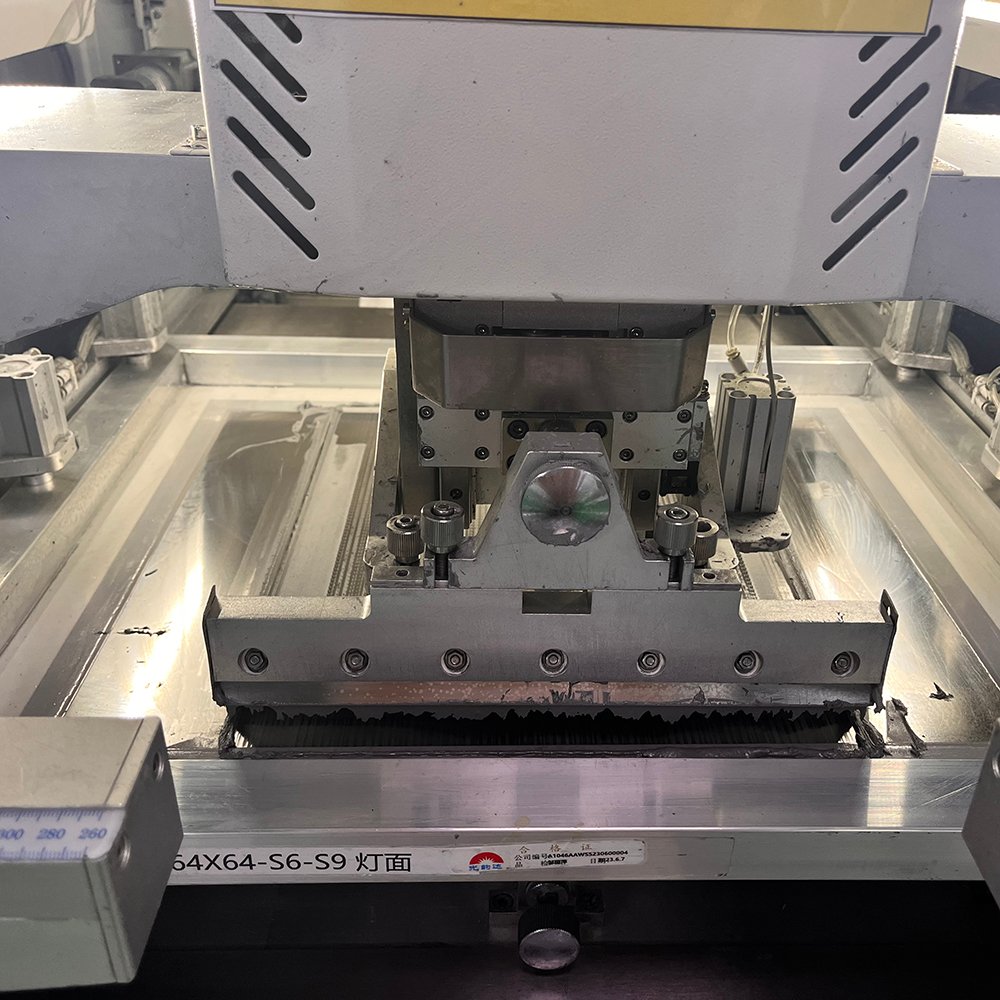

Put the circuit board in the fixture and then place it under a gravity tool to flatten it to the same level.

Use a tin brushing machine to evenly brush solder paste on the IC or lamp positions.

.

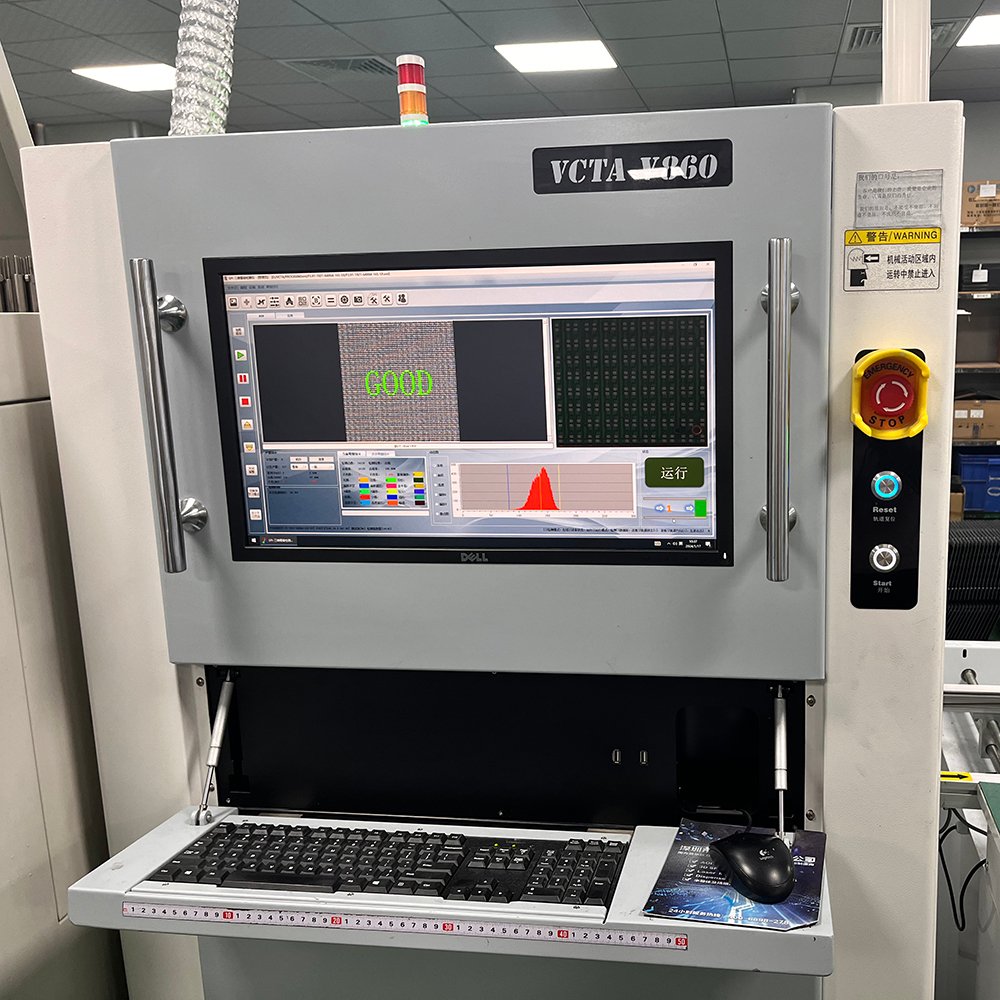

To ensure quality assurance, use testing machines to check if the solder injection points on the circuit board have been coated with solder paste.

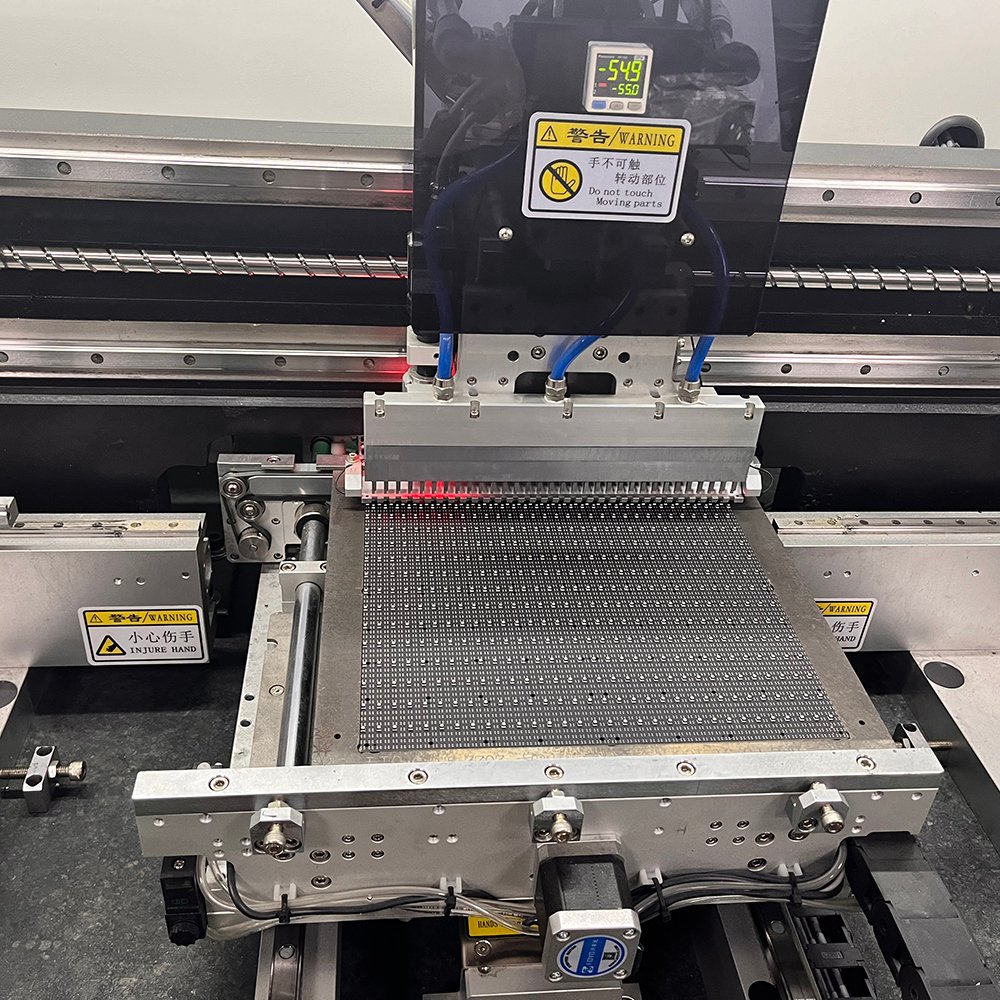

high-speed SMT machine can produce up to 1000 LED modules per day, ensuring timely delivery for our customers.

Use reflow soldering to fix the leds, ICs, capacitors and resistors on the circuit board.

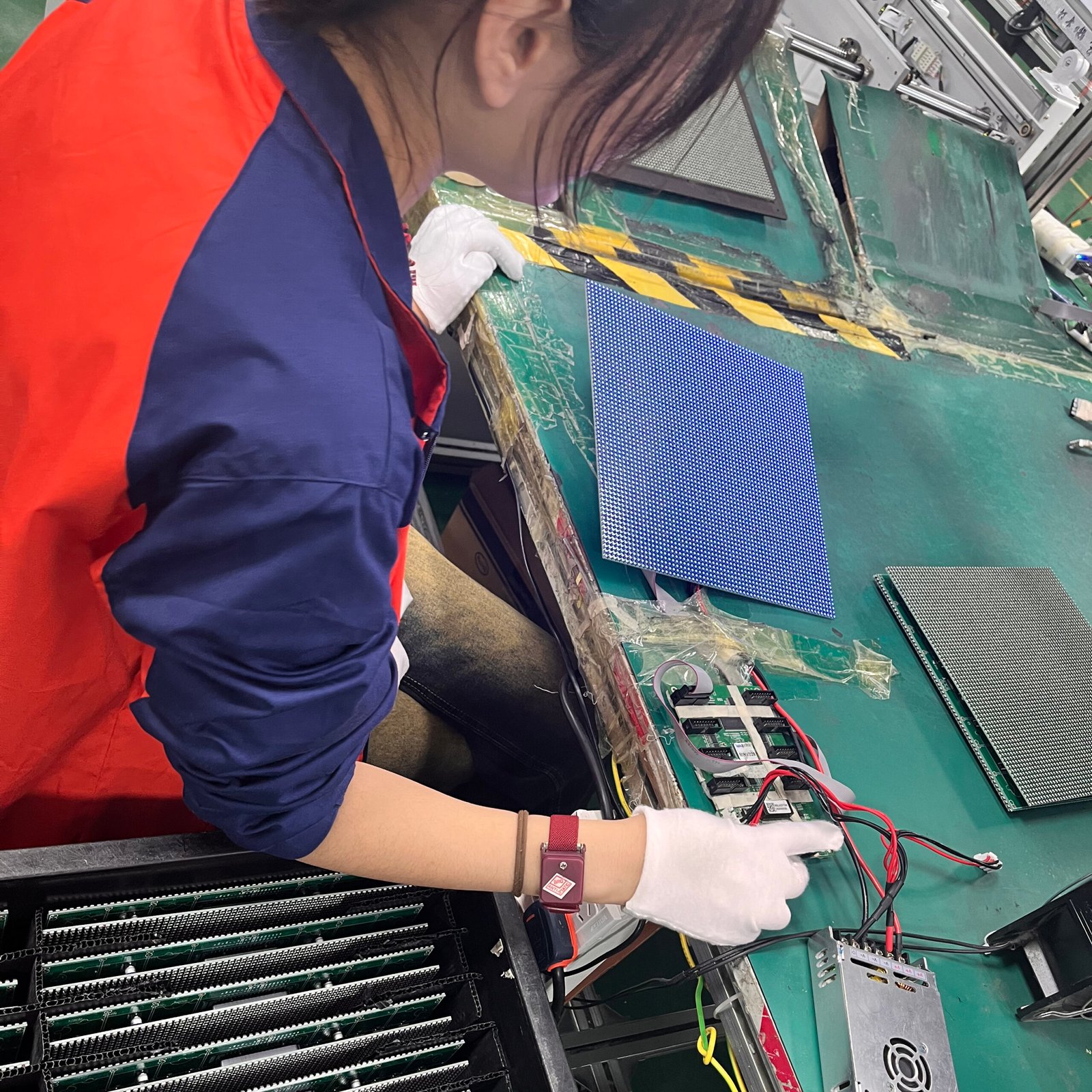

To ensure quality assurance,after fixing all components to circuit board, Will manually test the performance of LED modules.

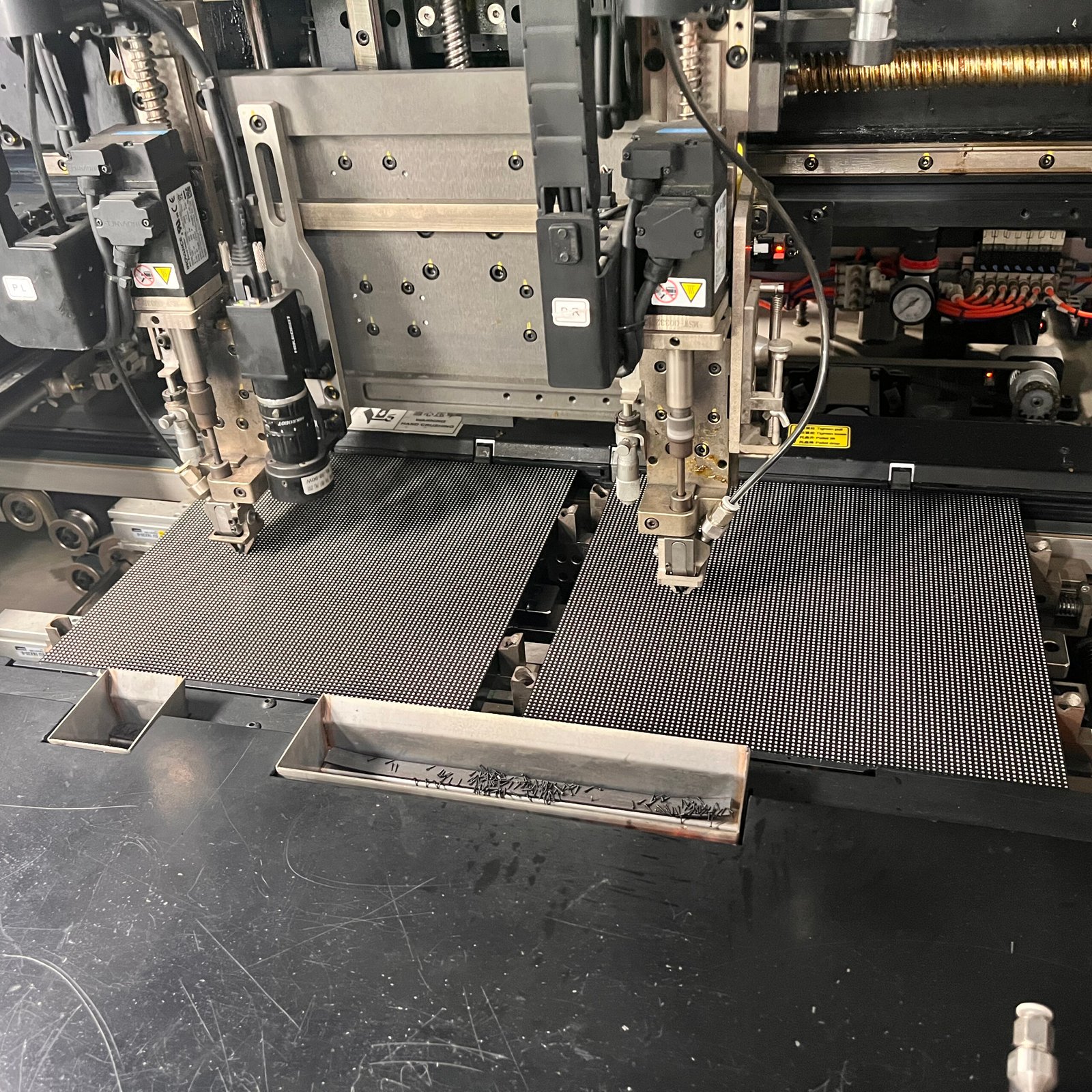

Automatic Screw Machine: Use the screw machine to fix the circuit board with the bottom shell.

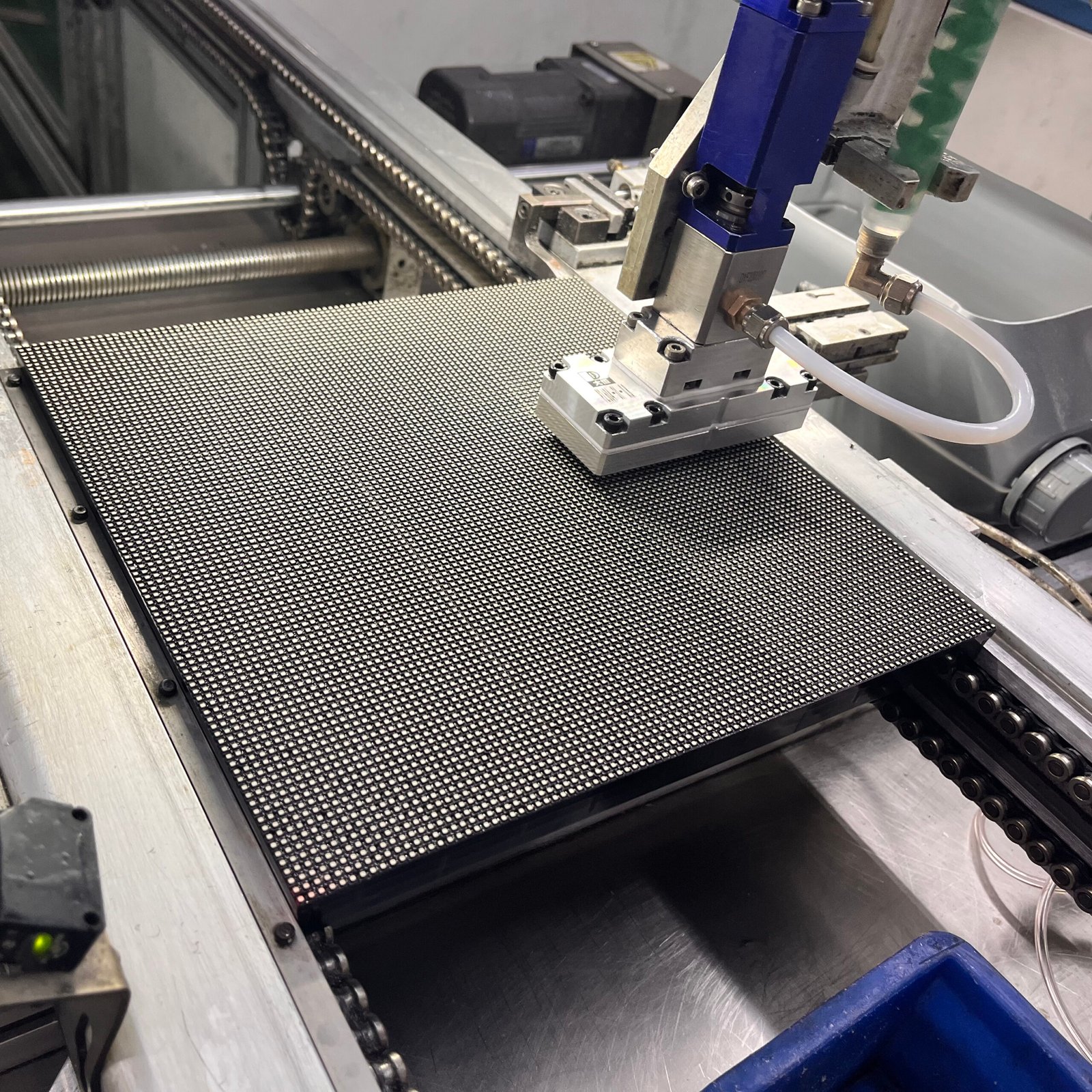

Automatic glue machine: Using an automatic glue machine to glue outdoor LED screen modules to achieve IP65 waterproof level.

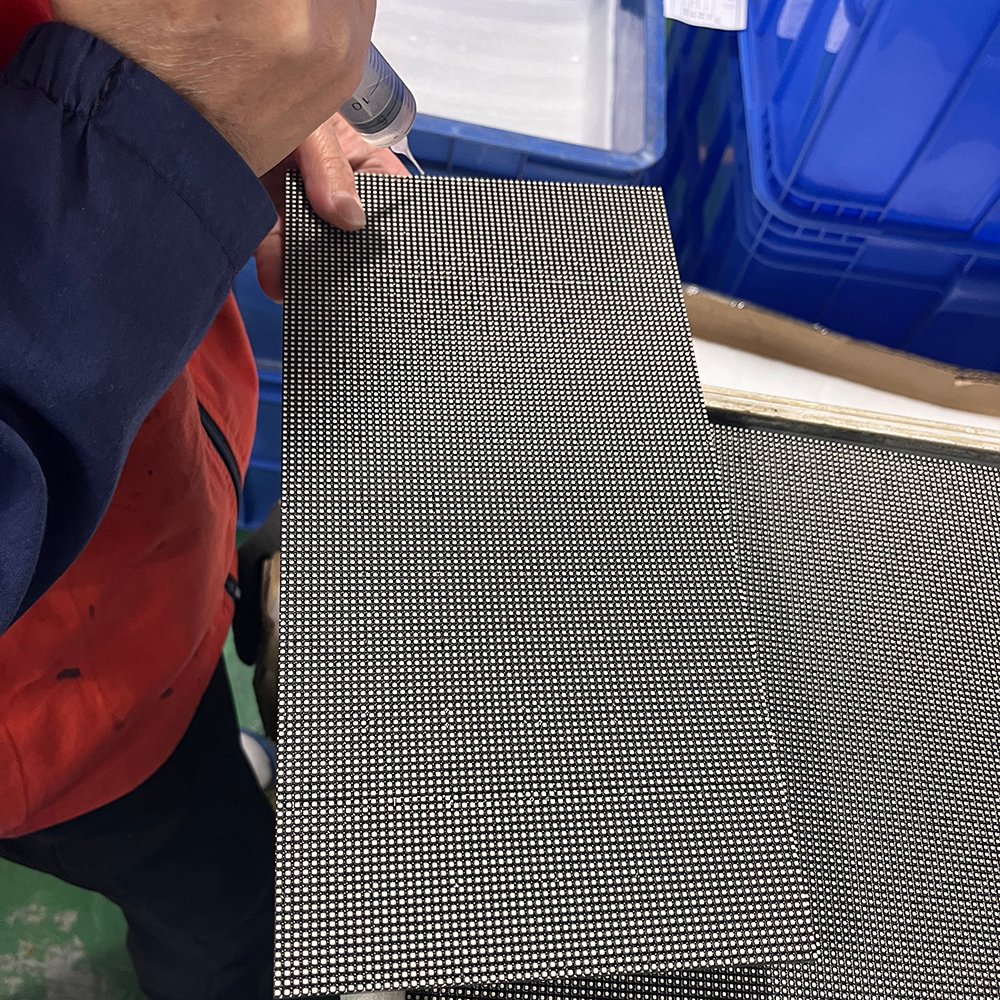

The third door to quality assurance:Check the sealing condition of each module to ensure 100% waterproofing of the product.

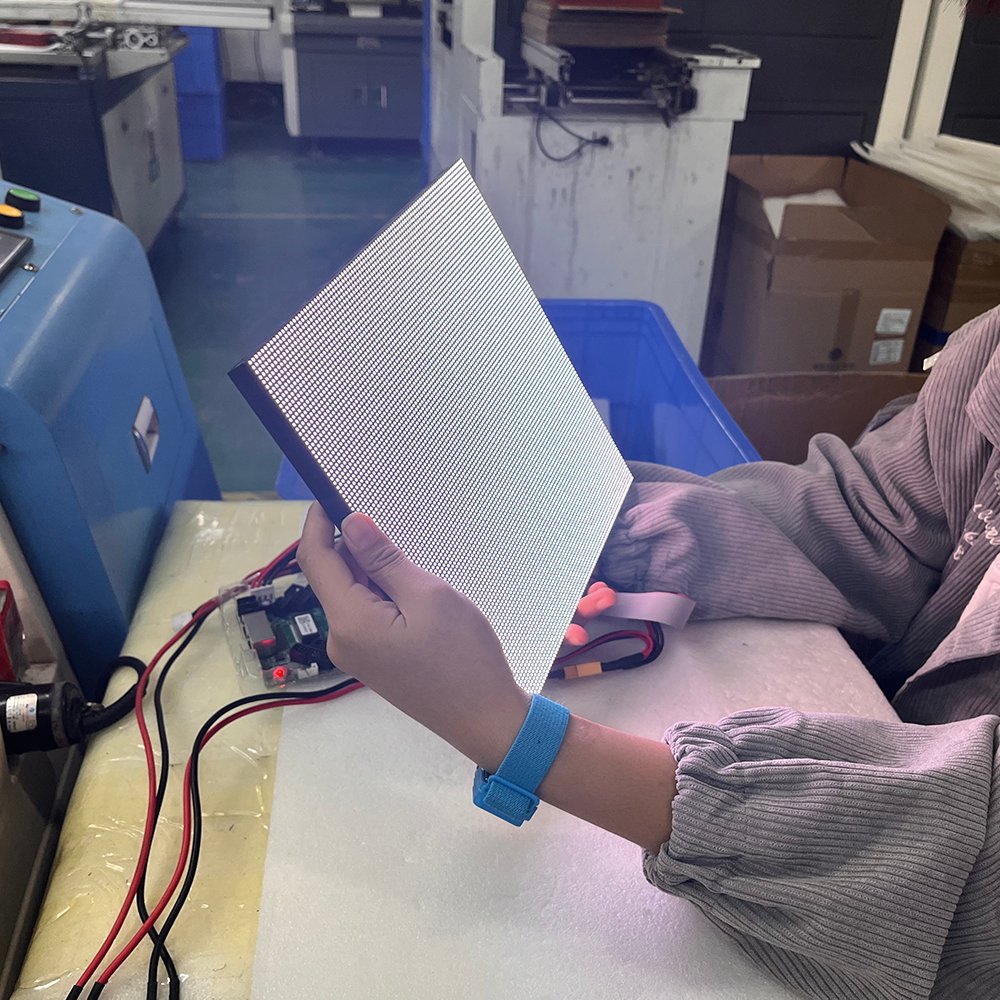

The fourth step in quality assurance is to manually test the performance of the finished LED screen module.

Aging test: The finished led screen module undergoes a 48 hours aging test to ensure product quality.

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix”@dhxsigns.com“.

We will contact you within 1 working day, please pay attention to the email with the suffix”@dhxscreen.com“.

Fill out the form below, and we will be in touch shortly.