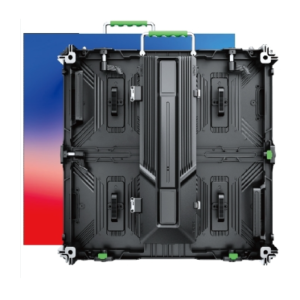

Description

| 500*500B Die Cast Aluminum Case | |

| Size | 500mmx500mmx76mm |

| Weight | 10KGS(incude led module and power supply |

| Material | Aluminum |

| Number of Modules per Cabinet | Nine modules per cabinet |

| Installation | Crane Girder hoisting and fixed installation |

| Color | Dark Gray |

| Sandard accessories | 2 Positioning pins.2 Install the power strips 1.3 connection pieces.4 quick locks |