1. Product Overview

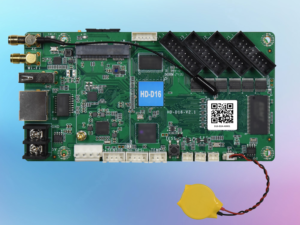

Thank you for reading this post, don't forget to subscribe!HD-D16 Full color asynchronous Control System is an LED display control system for Lintel led screens, car

screen and full color small size led screens,4 standard HUB75E ports on board. It is equipped with Wi-Fi module,

support mobile APP control and Internet remote cluster control.

Supporting computer control software HDPlayer, mobile phone control software LedArt and HD technology

clouds management platform.

Support USB interface to update the playback program; support external various environmental monitoring

sensors; support playback of video, pictures, Gif animation, text, WPS documents, tables, clocks, timing and other

program content; support 60Hz frame rate output.

2. Product Features

Input:

1. Support 1 channel 100M communication network port for debugging parameters, sending programs and

accessing the internet;

2. Support 1 channel USB communication interface for updating programs and expanding capacity;

3. Support 1 channel sensor interface, 1 channel GPS interface and 1 channel temperature sensor interface.

Output:

1. Maximum control range of 65,000 pixels, supporting the widest 1024 pixels or the highest 256 pixels;

2. 4 HUB75E interfaces on board.

3.Function:

1. Standard Wi-Fi module, support AP mode and STA mode, in STA mode the device can connect to the nearby

Wi-Fi network (operating distance recommended within 15M);

2. Support 1 channel video window playback;

1. 3. Support 4G access to the small gray cloud platform Internet remote cluster management (4G module

optional); 4. Support 3 groups of CTRL function, switching detection, detection of 12V level input, control the

bright screen/black screen/switching the program;

4. Support for UART communication;

5. Support for 1 channel RS-232 or RS-485 communication (optional);

6. Support for video, Support video, picture, text, animation word, clock, neon background, animation

background and other special effects;

7. Support optional external relay, remote control of the power supply.

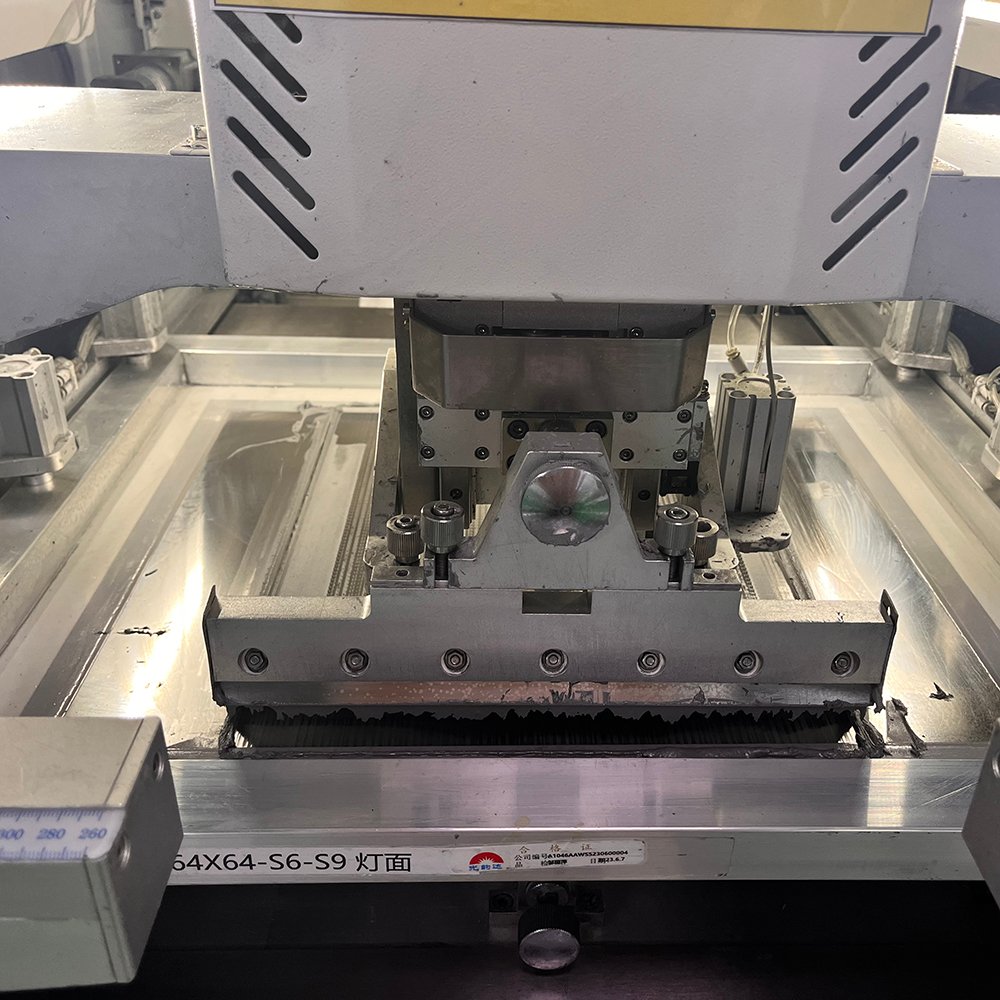

Put the circuit board in the fixture and then place it under a gravity tool to flatten it to the same level.

Use a tin brushing machine to evenly brush solder paste on the IC or lamp positions.

.

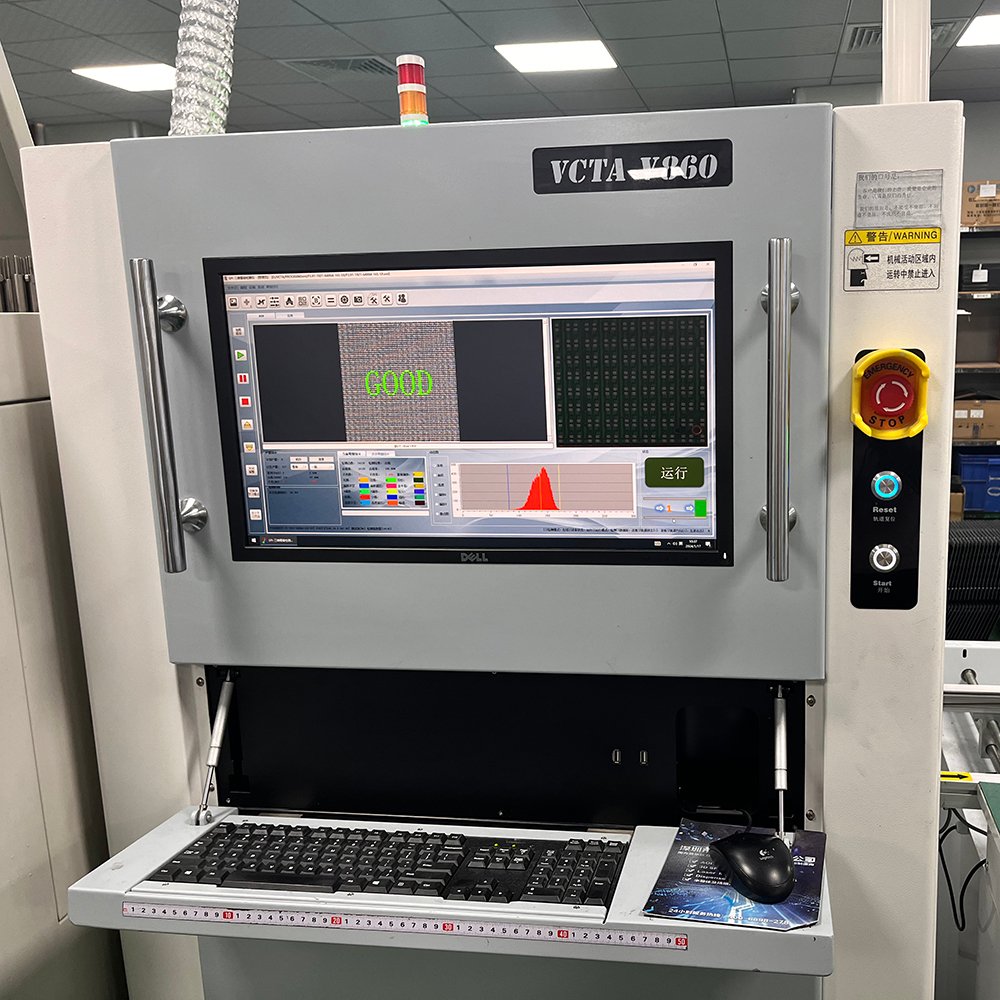

To ensure quality assurance, use testing machines to check if the solder injection points on the circuit board have been coated with solder paste.

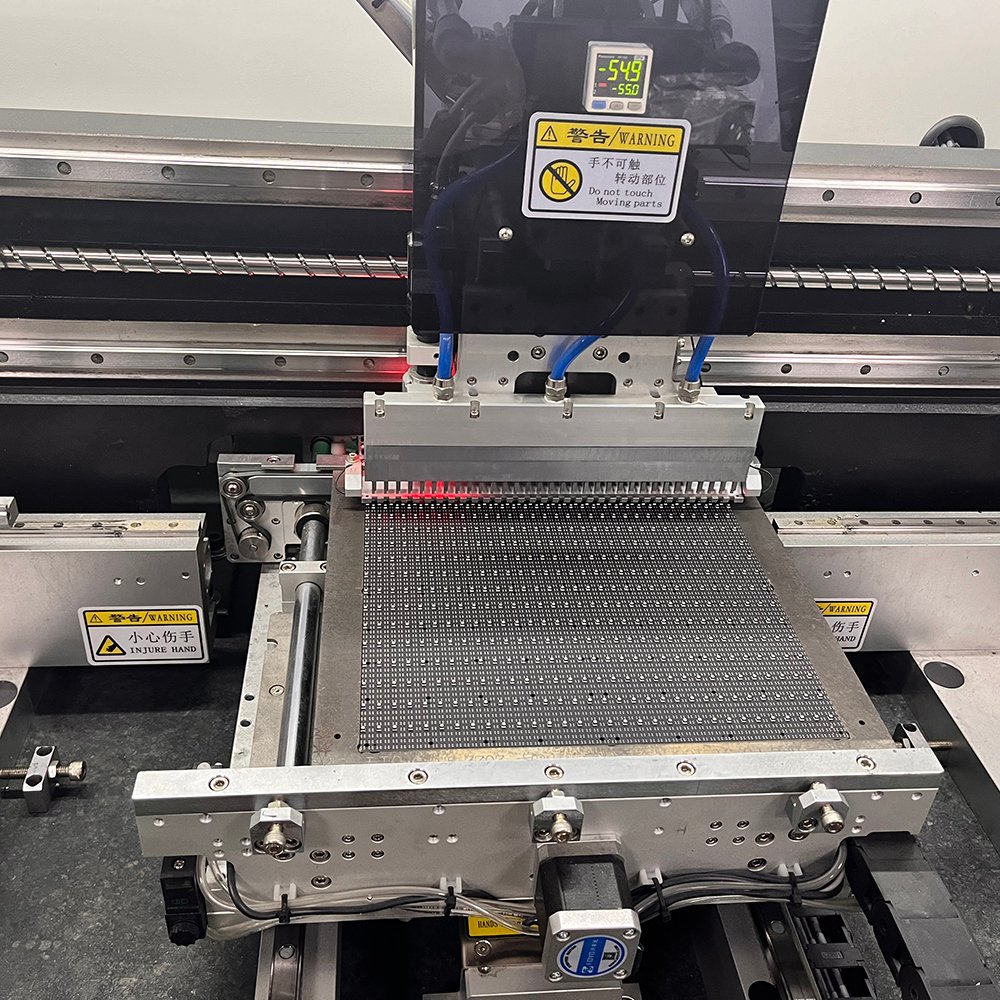

high-speed SMT machine can produce up to 1000 LED modules per day, ensuring timely delivery for our customers.

Use reflow soldering to fix the leds, ICs, capacitors and resistors on the circuit board.

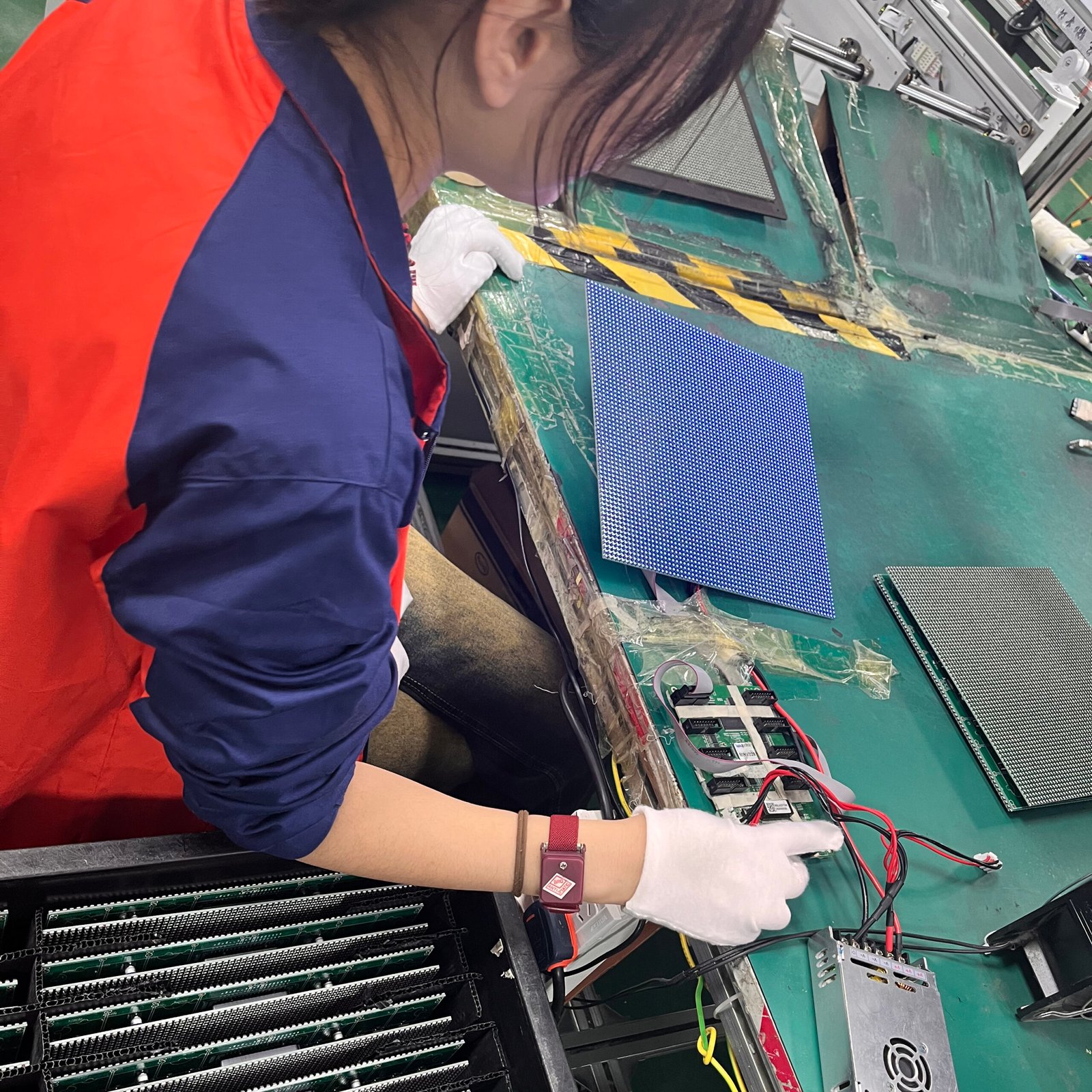

To ensure quality assurance,after fixing all components to circuit board, Will manually test the performance of LED modules.

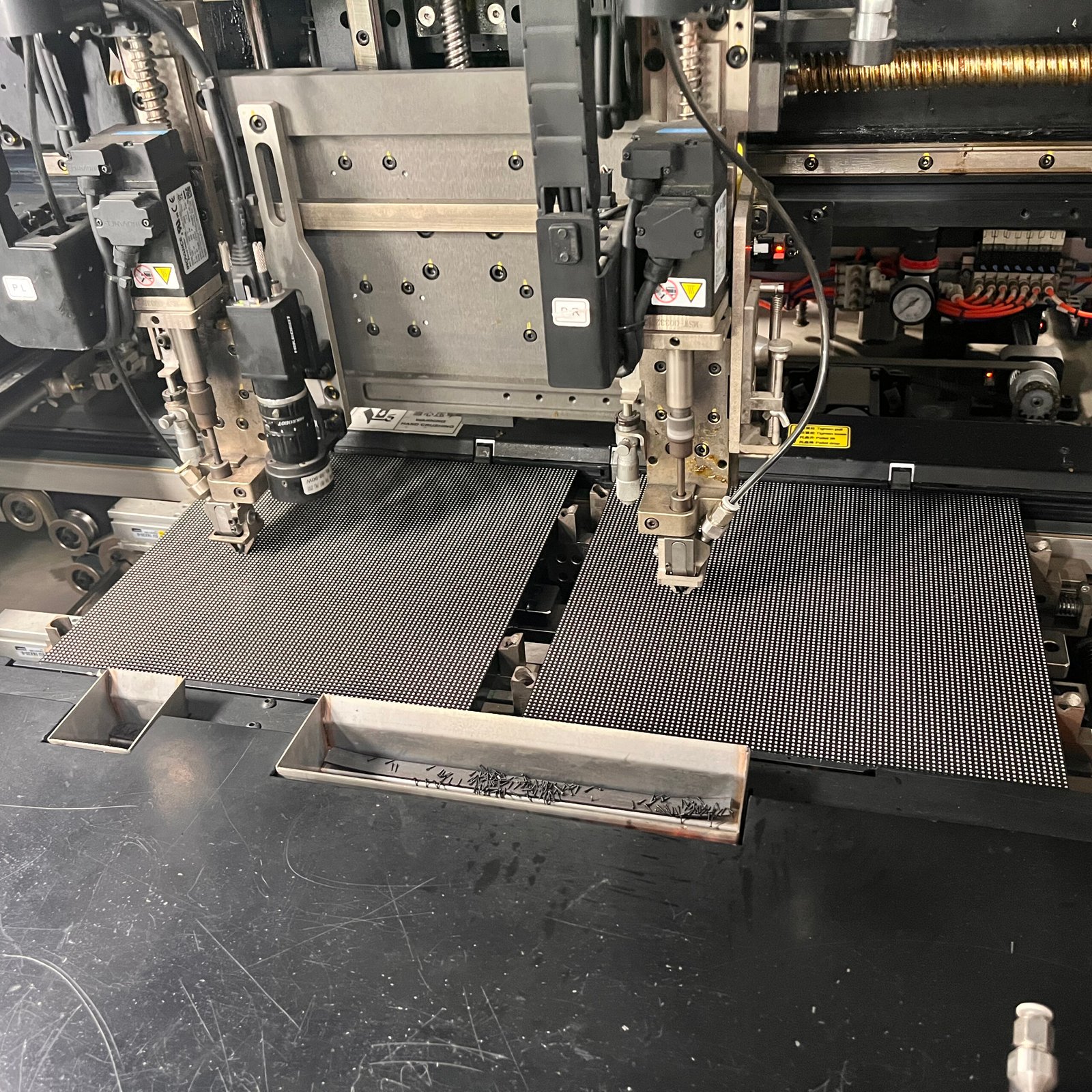

Automatic Screw Machine: Use the screw machine to fix the circuit board with the bottom shell.

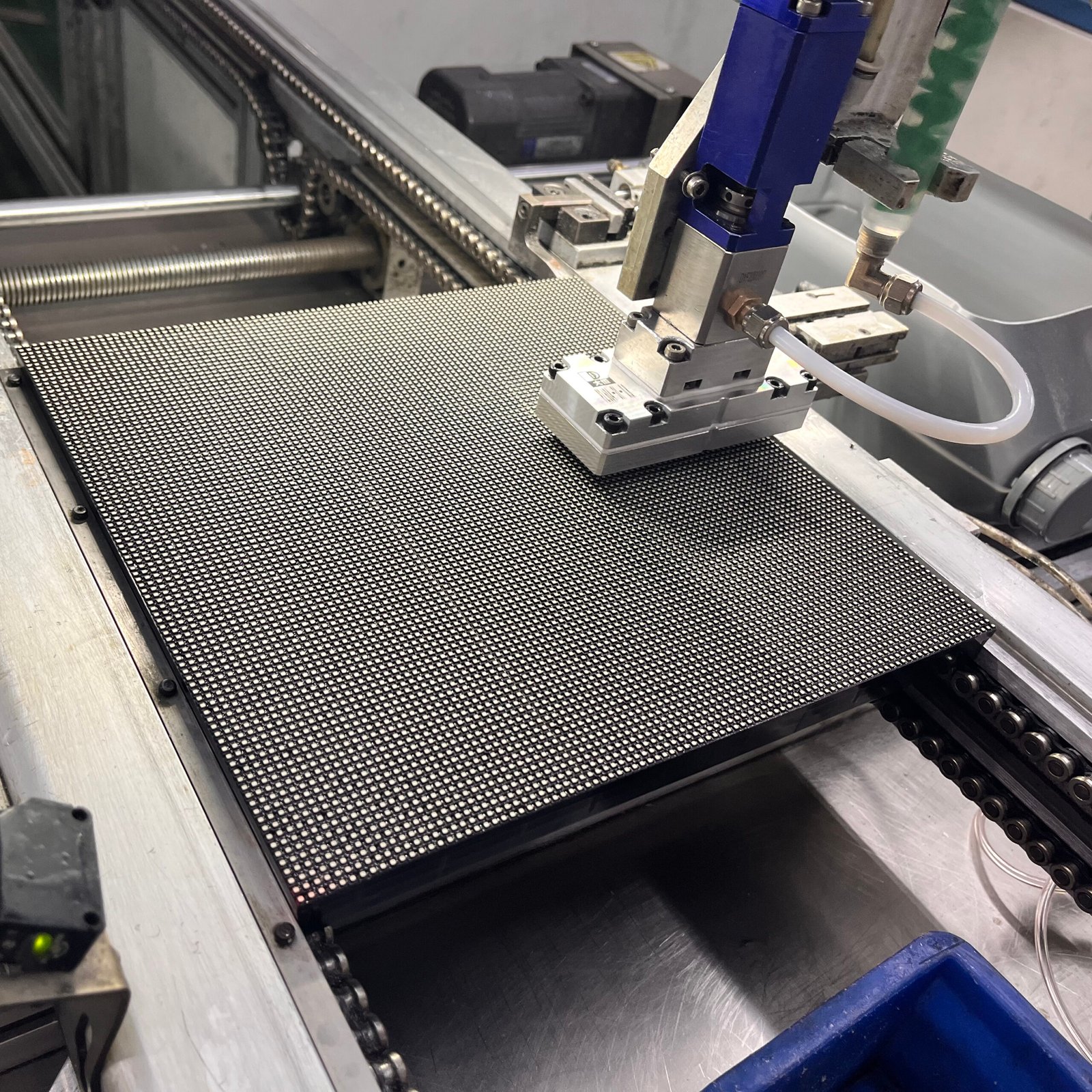

Automatic glue machine: Using an automatic glue machine to glue outdoor LED screen modules to achieve IP65 waterproof level.

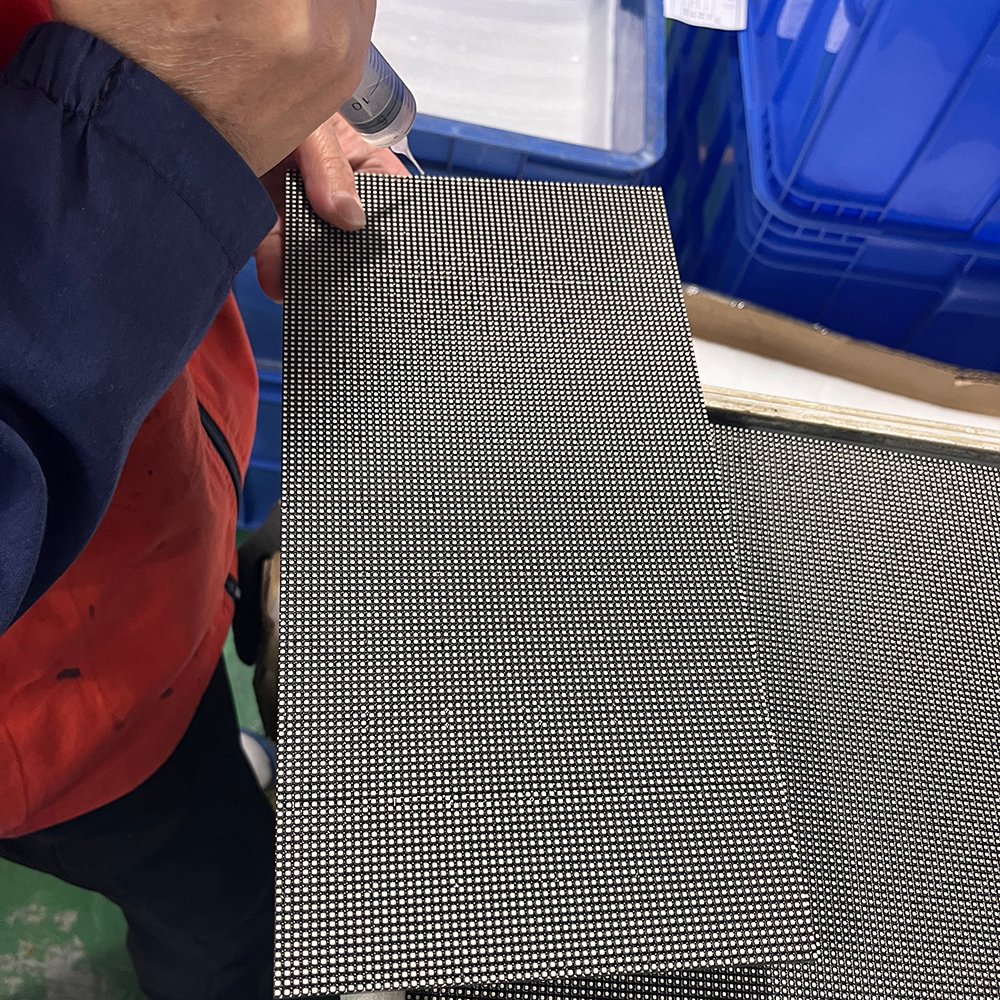

The third door to quality assurance:Check the sealing condition of each module to ensure 100% waterproofing of the product.

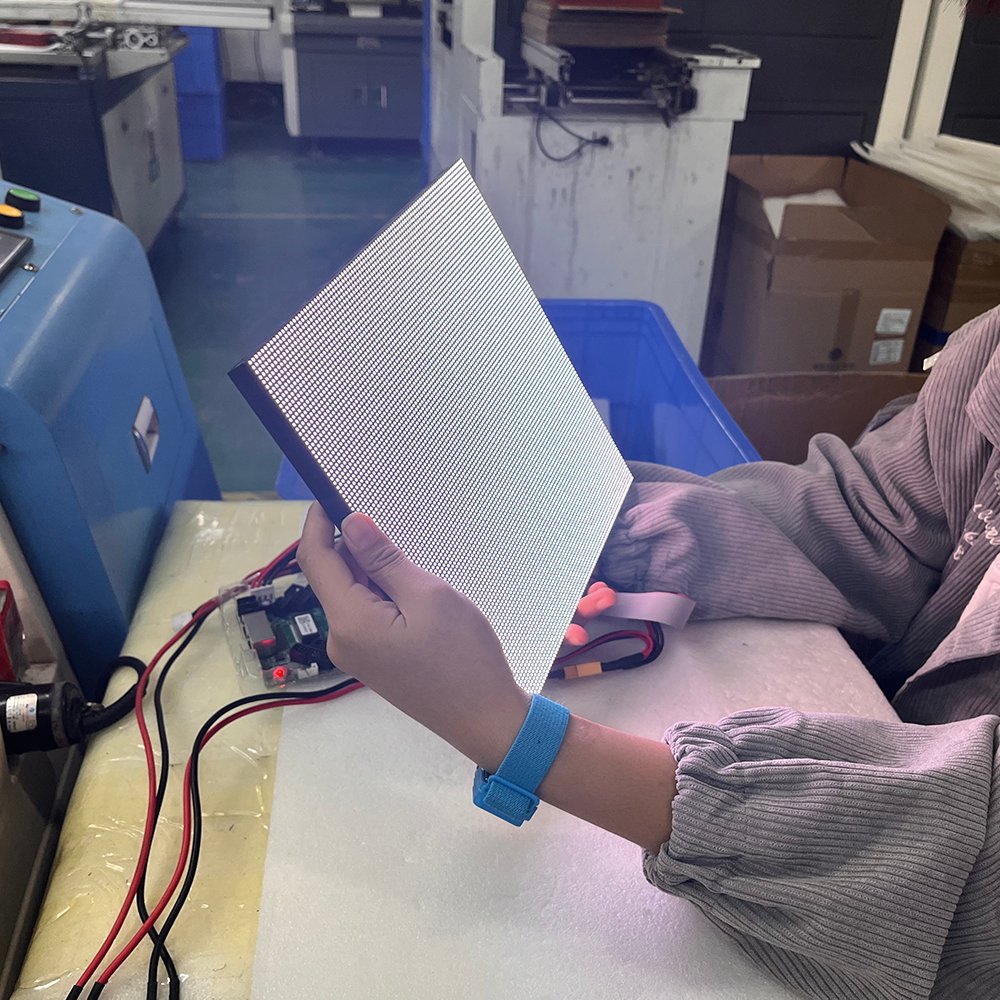

The fourth step in quality assurance is to manually test the performance of the finished LED screen module.

Aging test: The finished led screen module undergoes a 48 hours aging test to ensure product quality.

WhatsApp us

We will contact you within 1 working day, please pay attention to the email with the suffix”@dhxsigns.com“.

We will contact you within 1 working day, please pay attention to the email with the suffix”@dhxscreen.com“.

Fill out the form below, and we will be in touch shortly.